Talked about this issue so many time, need to assume that response factor of each component is identical. However, we always negelect that at the assay of total impurities in the samples were performed by normalization method.

Talked about this issue so many time, need to assume that response factor of each component is identical. However, we always negelect that at the assay of total impurities in the samples were performed by normalization method. So I only recommend to use this method to estimate the relative amounts of small impurities or degradation compounds in a purified component at the specific detector wavelength, that is chromatographic purity.

So I only recommend to use this method to estimate the relative amounts of small impurities or degradation compounds in a purified component at the specific detector wavelength, that is chromatographic purity. From my view, the Second maybe ensure a better Repeatability for your results.

From my view, the Second maybe ensure a better Repeatability for your results. or if I were you, I will use manual integrate to get a decent result with batch options.

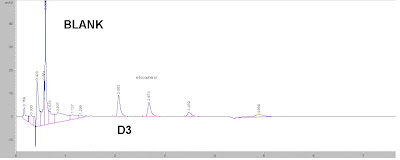

At the same time, I always double that the column maybe over-load, that mass of analyte per injection is too high, don't you think so?